Hotline:400-0088-068

Tel:18926010188

Email: nanofront@163.com

ADD:Room 602, Building 33, Phase III of Qianlin Shanju, Wulian Village, Longgang District, Shenzhen City.

SNT Concrete Sealing Hardener is a liquid hardener that is non-toxic, odorless, and non-flammable. It is used for the hardening of concrete floors, offering functions such as hardening, wear resistance, dust prevention, seepage prevention, and luster.

SNT Concrete Sealing Hardener penetrates the concrete deeply, reacting chemically with the components within the concrete, changing the structure of the concrete, and forming a dense three-dimensional whole. This results in a reduction of the micro-pores in the concrete and an increase and strengthening of the gel structure. Consequently, the strength, hardness, and wear resistance of the concrete floor are significantly enhanced, capable of blocking the erosion and weathering from external substances such as oil and alkali, achieving permanent sealing, hardening, and dust prevention.

SNT Concrete Sealing Hardener is not an organic coating, and it does not experience aging, wear, or peeling. The sealed and hardened floor itself does not produce dust, and foreign dust is easily removed. Daily cleaning and the friction from use will not make the floor rough but will instead produce a marble-like luster.

Constructing a floor with SNT Concrete Sealing Hardener eliminates the maintenance costs of the floor. There is no need to use high-priced, short-lived organic materials such as floor wax, polyurethane, or epoxy resin, nor is there a need for the cumbersome process of regularly removing the coating and re-applying it.

The surface of untreated concrete

The surface of treated concrete

Why do concrete floors need SNT Concrete Sealing Hardener ?

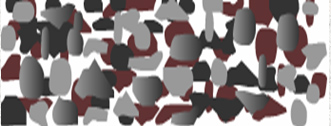

The inherent defects of concrete: Cement concrete materials consist of 3CaO.SiO2, 2CaO.SiO2, 3CaO.Al2O3, and 4CaO.Al2O3 .Fe2O3. They undergo hydration reactions to produce Ca(OH)2. As early as the 7th International Cement Chemistry Conference held in Paris in 1980, F.H.Wittman introduced the concept of porosity and pointed out that cement concrete is a non-homogeneous multi-phase system, typically composed of unhydrated cement clinker particles, hydrated cement, water, a small amount of air, and an air network occupied by water and voids. Therefore, cement concrete is a solid-liquid-gas three-phase porous system. Schematic diagram of the concrete structure."

Concrete Structure Schematic Diagram

The hydration reaction equation of silicates cement can be described in English as follows:

2(3CaO.SiO2)+6H2O = 3CaO.2SiO2.3H2O+3Ca(OH)2

2(2CaO.SiO2)+4H2O = 3CaO.2SiO2.3H2O+Ca(OH)2

3CaO.Al2O3+6H2O+ = 3CaO.Al2O3 .6H2O

4CaO.Al2O3 .Fe2O3 )+7H2O = 3CaO.Al2O3 .6H2O+CaO.Fe2O3 .H2O

Carbonation of Concrete (Weathering and Sanding)

Concrete is a porous body with many capillaries, pores, and bubbles of varying sizes inside. Carbon dioxide from the air first penetrates into the pores and capillaries of the concrete. It then dissolves in the liquid phase within the capillaries and reacts chemically with the hydration products such as calcium hydroxide, tricalcium silicate, and dicalcium silicate produced during the hydration process of cement, forming calcium carbonate. The main chemical reactions in this process are as follows:

CO2 + H2O →H2CO3

Ca(OH)2 + H2CO3 →CaCO3 + 2H2O

3CaO·2SiO2 ·3H2O + 3H2CO3 →3CaCO3 + 2SiO2 + 6H2O

The carbonation process of concrete is a complex chemical reaction that occurs simultaneously in the gas phase, liquid phase, and solid phase. Carbonation reduces the alkalinity of concrete, destroys the passive film on the surface of steel reinforcement, leading to corrosion. Additionally, carbonation of concrete can intensify the shrinkage of concrete, leading to cracks and structural damage, which is very detrimental to the durability of reinforced concrete structures.

Bleeding and Segregation of Concrete (Dust Generation)

During the construction process of concrete, the phenomenon where solid particles sink and water rises and exudes on the surface from the time of pouring to the beginning of setting is called bleeding. Due to the bleeding and segregation of concrete, cement paste and fine particles float on the surface, forming a weaker layer.

Bleeding in concrete is very harmful. It increases the water content on the surface of the concrete, producing a large amount of laitance. The hardened concrete has uneven strength from top to bottom, with the upper layer being weaker than the lower layer. This results in a large amount of dust that is prone to peeling off on the surface of the concrete. Its surface wear resistance is very poor, leading to dusting and powdering phenomena.